MES is a ONE STOP SHOP YOUR PIPELINE MATERIALS VERIFICATION PROGRAM.

The Pipeline and Hazardous Materials Safety Administration (PHMSA) Mega-Rule (Part 1) requires pipeline operators to maintain adequate records to substantiate and validate the material properties of their pipeline system through a Material Verification (MV) (§192.607) program . Whether you are just getting started, or complimenting an established §192.607 compliance program, MES can assist you through both in-field inspection and laboratory services.

Our services focus on rapidly providing the data required for your internal compliance program, supplementing internal resources with decades of metallurgical expertise. Our reports allow our clients to mitigate threats, determine gaps in material property information, and generate records for maximum allowable operating pressure (MAOP) within a piping system. We encourage you to contact our engineers or explore our services below to see how the MES team can assist you with your pipeline materials verification program.

IN-FIELD INSPECTION SERVICES

Whenever a pipeline operator performs an excavation or dig, it provides an opportunity to gather data through non-destructive inspection. MES provides NDT technicians to accompany you for obtaining information on pipe thickness, dimensions, chemistry, weld type, mechanical properties, and material microstructure through in-field replication. Additionally, we can provide in-line inspection (ILI) verification.

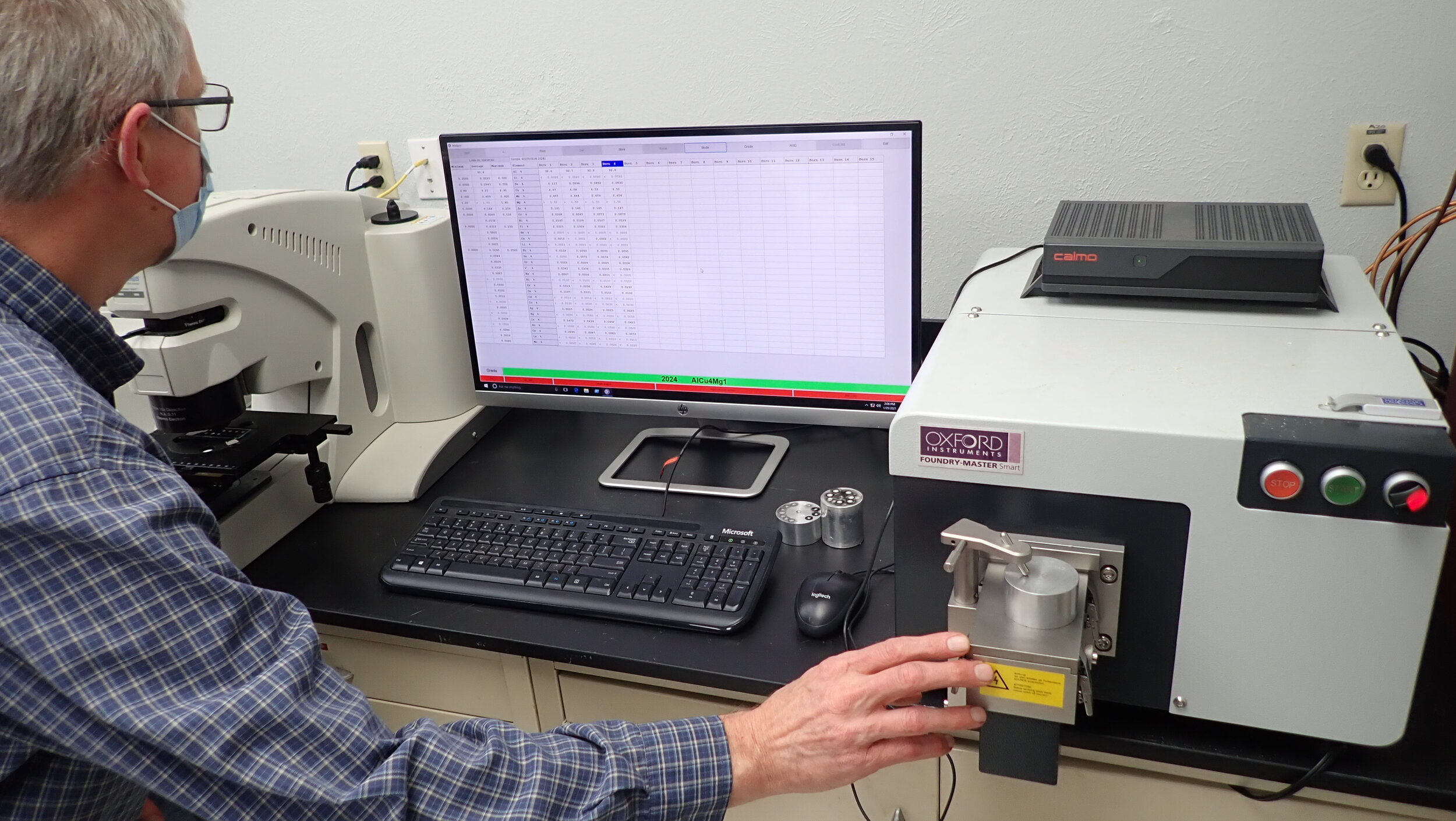

LABORATORY SERVICES

When destructive testing is permitted, our full service test laboratory is equipped to receive all sizes of ring specimens extracted from the field. These sections are machined into test specimens for direct measurement of tensile strength, hardness, Charpy impact, weld type, and chemical composition. These properties are graded by our team of metallurgical engineers to API specifications.

DATA REVIEW & REPORTING

MES is more than just a test lab. Our experts can help you grade to API 5L standards and quickly integrate data into existing systems for effective data management. On staff metallurgists can help identify threats to pipeline integrity and determine expected useful life based on test results.